Choosing the right loader involves weighing key trade-offs between stability and mobility. For instance, a track loader provides superior traction and control on diverse conditions like mud or snow, but a wheel loader is faster and easier to transport between job sites. This decision is critical because it impacts everything from your budget and maintenance costs to overall job site efficiency. Your applications, job site conditions, budget and equipment transportation needs are essential considerations before investing in a new piece of equipment.

Comparing Tracked vs. Wheeled Heavy Equipment

Tracked and wheeled equipment primarily differ in weight distribution. Tracks spread weight over a wider surface area, while wheeled equipment concentrates weight on four points.

A tracked piece of equipment lowers ground pressure because its tracks spread the machine’s weight out, reducing pounds per square inch. A wheeled machine increases ground pressure because its weight places more pressure on the smaller surface areas under the wheels. Wheels cut into the ground deeper, while tracks “float” over the ground.

These factors impact how equipment performs on different terrain, making each type ideal for different applications and jobsites. Choosing the right equipment enhances stability, helping you maintain control to boost efficiency and prevent struck-by accidents.

Advantages of Tracked Equipment

A tracked machine’s lower ground pressure and durable tracks offer the following advantages:

- Smoother travel: Tracks tend to absorb more energy than wheels, reducing instability when you move across hollows, bumps and dips. This results in smoother travel across rugged or uneven terrain.

- Traction and control: A tracked machine has more traction than a wheeled machine, helping operators maintain control on slopes or soft ground.

- Turf protection: Lower ground pressure results in less turf damage. You can work on soft ground with minimal disturbance. Using a tracked machine can help you avoid leaving deep ruts on the ground or significantly compacting the soil.

- Ability to operate in diverse conditions: A tracked machine’s stability, traction and wider weight distribution enable you to work on a wide variety of jobsites. Tracks can travel in jobsites with rugged terrain, muddy conditions, wet ground, sand, loose soil or snow.

Advantages of Wheeled Equipment

Wheeled equipment also comes with advantages. You can enjoy the following benefits when you operate wheeled equipment:

- Versatile capabilities: Various attachments fit wheeled equipment, expanding what you can do with it. Whether you need to spread materials, plow snow or trench the ground, a wheeled machine offers the versatility you need.

- Lower upfront cost: Wheeled equipment tends to have a lower upfront cost than tracked equipment because wheels require a simpler, less robust undercarriage.

- Fewer maintenance needs: Wheeled equipment has fewer moving parts, which reduces general wear and tear. You can generally expect faster, less frequent maintenance on wheeled equipment, lowering your overhead costs and increasing your equipment uptime.

- Greater longevity: While tracked equipment is highly durable and long-lasting, wheeled equipment tends to have a longer lifespan. Their mounted components and brakes tend to last longer.

- Speed on hard surfaces: Wheeled equipment operates better on hard, flat surfaces such as asphalt and concrete. It also travels faster, making it an excellent option if you need to move quickly across large worksites.

- Easier transportation: A wheeled machine’s ability to operate on hard surfaces also makes it easier to transport. In many cases, you can drive wheeled equipment on the road, eliminating the need to haul it with a trailer. This makes it easier to move equipment between jobsites.

- Maneuverability: Wheeled equipment is easier to maneuver and operate in tight spaces. It’s typically more compact than tracked equipment.

Do You Want a Tracked Machine or a Wheeled Skid Steer?

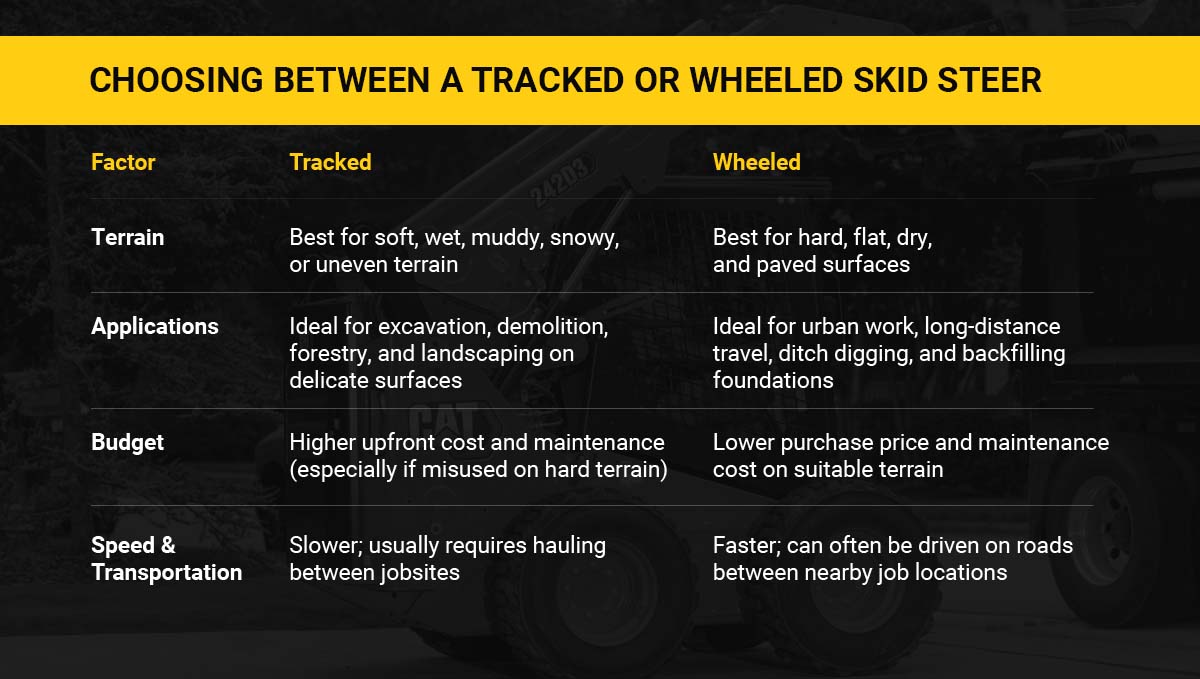

Tracks and wheels offer unique advantages. When choosing between a tracked or wheeled skid steer, determining which works better depends on these factors:

Terrain

What type of terrain do you primarily work on? Tracked equipment is best for working on soft ground or tackling rough terrain. It’s also a fantastic option if you need to work in wet, muddy or snowy conditions.

Wheeled equipment is ideal if you mostly work on hard surfaces. Flat, hard surfaces are abrasive to tracks, causing significant wear to tracked machines. Wheels glide across paved surfaces with ease.

Applications

Consider your main applications and tasks before choosing equipment. Tracked machines are typically the best option for applications such as excavation, demolition, forestry and landscaping on sensitive surfaces.

You should choose wheeled equipment if you mainly work in urban environments or need to make multiple trips over long distances. Its speed and mobility also make it a great option for tasks such as digging ditches or backfilling foundations.

Speed and Transportation Requirements

Is speed and easy transportation a priority in your projects? Tracked equipment often requires hauling, so it’s important to factor this into your decision. Your crew can drive wheeled equipment on the road, making it easier to deploy it on different projects. Consider how often you’ll need to transport equipment between jobsites and how you want to transport it.

Budget

How much do you want to spend on your upfront investment and ongoing equipment costs? Tracked equipment tends to have a higher upfront cost, and it usually requires more frequent maintenance than wheeled equipment. However, the amount of maintenance and repairs your equipment needs depends on the terrain. Limiting wheeled equipment to hard, paved surfaces and tracked equipment to soft ground can help reduce maintenance costs for each type of equipment.

Can You Convert a Wheeled Skid Steer to Tracks?

Yes, you can convert a wheeled skid equipment model to a tracked one. Use one of the following methods to transform your wheels to tracks:

- Over-the-tire (OTT) tracks: OTT tracks install over the equipment’s wheels. They’re designed to fit over standard tires, and you can choose between rubber or metal tracks. OTT tracks are a versatile option if you need more traction and flotation for select projects.

- Track conversion system: You can also replace your equipment’s wheels with a track conversion system. A full conversion is a more comprehensive solution if you need long-term, maximum traction.

What if You Need Tracked and Wheeled Equipment?

When it comes to tracked versus wheeled skid steers, sometimes both are the best option. If you work on soft ground and paved surfaces, you may need tracked equipment and wheeled equipment at different times. If this is the case, renting is an effective option. Renting allows you to use the equipment you need for each project without making a significant upfront investment. This can help you save money if you only need a wheeled or tracked machine for short-term use.

Find High-Quality Wheeled and Tracked Equipment From Carolina Cat®

Tracked and wheeled equipment offers excellent advantages, but choosing the right machine is essential. When you choose equipment based on your jobsite conditions and specific project needs, you can significantly boost safety and efficiency.

Carolina Cat® offers new tracked and wheeled equipment, including high-quality track loaders and skid steers. We also carry a wide selection of rental equipment to meet your temporary and short-term needs. Contact us to learn more about our equipment today.